The key to achieving operational excellence is to have real-time visibility of the whole process. Through SAP MII, companies can access processing data and have visibility of the shop-floor in real-time using a simple internet browser. With Neoris’Video Wall and Watch Portal, companies can enable collaboration, convergence, personalization and mobility facilitating the integration of the manufacturing and back-end processes. The “visibility challenge” is no longer an obstacle but an opportunity to increase productivity, improve business processes, achieve higher asset utilization, and lower the total cost of ownership.

Due to the current market pressures and product commoditization, operational excellence has become an even greater priority. The coordination and integration of various functions and business processes to improve decision-making is one of the most pursued goals by many companies. Then, how do companies build a path towards operational excellence? How can we improve a production process to lower costs and create a competitive advantage (in price and quality)? Without any doubt, one of the first steps down this path begins with a deep and thorough view of the production process, namely VISIBILITY!

Without visibility, production supervisors or manufacturing operators usually struggle to get a real-time sense of what is happening during their shifts. Their daily challenges are: knowing if production goals are being achieved on a real-time basis; getting accurate real-time status reports of planned work orders; current availability of supplies; utilization levels of machinery; the level of quality compliance; and what is really happening on any production line at any given time of the day. The constant questions are: What is the current status of my company’s production processes? Are there any malfunctioning machines? What is the impact of these events on costs, delivery commitments, prices, and inventory stocks?

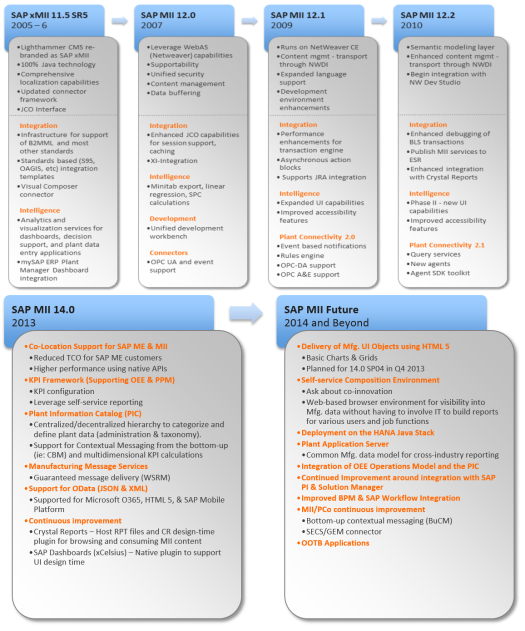

The challenge is having all this data, at the right level of detail, readily available to the line managers who need it the most and in real-time. A typical shop-floor environment may have between fifty and eight-hundred different systems (industrial automation and information systems). Often, these are legacy systems which have been in use for decades. So, the challenge boils down to accessing and integrating this high volume of unstructured data and then providing this information in one place, which is easy to get, and in real-time. SAP addressed this challenge in 2005 with the introduction of their solution aimed at the integration and delivery of intelligence to the shop-floor and for the entire enterprise. This solution is commonly known as SAP MII (SAP Manufacturing Integration and Intelligence).

SAP MII revolutionized the market by providing a simple way to access processing data and providing visualization of any shop floor information in real-time, using a simple internet browser. SAP MII maximizes the outcomes of existing applications without the need to create new control systems or databases, while avoiding any data duplication. With a quick deployment timeframe and low total cost of ownership (TCO), this tool allows for the creation of composite applications for the manufacturing environment without the need to build anything from scratch. As such, SAP MII strengthened the SAP NetWeaver platform allowing an automatic and real-time integration enabling data exchange between the shop-floor and ERP systems, thereby allowing the integration of manufacturing with back-end processes.

Given this challenge, and presented with the SAP MII solution, Neoris created a Center of Excellence for the Perfect Plant in 2008. The Perfect Plant concept was created by SAP in an effort to help remove the boundaries between the front-office and the shop-floor. Through extensive experience gained in large industrial projects, deep SAP expertise, and track record of innovation, Neoris envisioned an opportunity to enhance the theme of “visibility” utilizing SAP MII.

To address the challenge head-on, two innovative solutions were brought to the table: Video Wall and Watch Portal. The Video Wall provides collaboration and convergence, while the Watch Portal enables personalization and mobility of relevant information to the production process.

The Video Wall solution appeared after evaluating a major dilemma: how to converge all of the business production supply chain information in real-time while allowing several employees to work together by “handling” and “publishing” this information into a single environment so they can come up with an collaborative and consistent decision? Simply put, the problem was that the systems that monitor the supply chain process managed each sector separately and each employee had access to data in his own area or process, individually, making it difficult to share information.

The big challenge here is to give Operations Management a tool to see coordinated, dynamic and real-time data, presented in an easy way to help them make joint management decisions. Therefore, by combining the use of the SAP MII tool with the Video Wall, Neoris was able to integrate and present all the necessary information from across the entire enterprise in an easy and visually appealing way – using large integrated LCD HD screens located in an Enterprise Command Center (ECC).

Data displayed in the ECC is enriched with symbols that indicate the various statuses of planning and production control, equipment availability, production orders in execution, inventory levels, etc. The application also provides various logistics data (supply and disposal) of the process, integrated with GPS equipment and cameras showing real-time images of the areas with active alerts.

All this information is accessed through the operator’s terminal, in an easy to use way that allows him to “drill-down” into the details and verify the existence of any problem. The Operator can also publish this information to the large screen by means of the existing application’s interface in the terminal (similar systems only allow a so called “controller” to do this). At the same time, another user can access information from other areas and publish found problems on the same screen. These allows everyone to concurrently and immediately access all relevant information, quickly decide what must be done, and take immediate action. Employees who are outside the command center may also interact with this environment by other remote methods, such as iPhones.

Neoris has recently implemented this solution in a Enterprise Command Center (ECC) at USIMINAS. USIMINAS is one of the largest steel manufactures in Brazil, accounting for nearly 30% of all steel produced for that country. Their ECC screen is approximately 43 feet wide by 6 feet high. In this ECC, 28 operators perform and monitor the entire end-to-end steel production process. This process begins with the entry of raw materials and finishes with the shipment of finished products. The Neoris solution met all the client’s business requirements: (a) the existing systems were integrated and employees have a holistic view of the process; (b) everyone can access relevant information required to execute the production logistics in a single, unique environment; (c) they can quickly respond to questions related to production, logistics, equipment and materials, while monitoring the manufacturing KPI’s in real-time.

However, the lack of visibility challenge does not end here. In order to have everyone responsible in the production process reach their individual goals, they need to have a personalized view of the indicators specific to their areas of responsibility and they need to be able to access all their information at any time, in real-time, from anywhere.

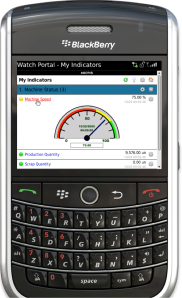

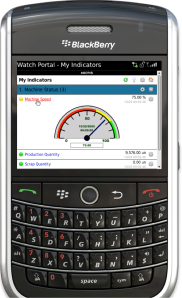

To meet this need, Neoris created the Watch Portal solution. This solution allows each employee to access shop-floor databases and create their own personalized control panel. This control panel can be accessed from anywhere, securely, via a web browser on a laptop or mobile device (such as iPhone, Blackberry, PDA’s, etc.), thus meeting all of the mobility needs.

To meet this need, Neoris created the Watch Portal solution. This solution allows each employee to access shop-floor databases and create their own personalized control panel. This control panel can be accessed from anywhere, securely, via a web browser on a laptop or mobile device (such as iPhone, Blackberry, PDA’s, etc.), thus meeting all of the mobility needs.

Moreover, this solution has an alerts monitoring feature that allows the management of exceptions, allowing employees to receive email alerts and messages on their mobile device if any of their monitored indicators were to exceed the defined control limits.

The key differentiators between the Neoris Watch Portal and other products on the market is that the Neoris solution allows an End User to configure key indicators intuitively, without requiring IT support. Additionally, it uses the SAP MII application to access any data located on any the following manufacturing systems: Control and Automation HMI / SCADA (Ci Technologies Citect, Iconics Genesis32, InBatch, InControl, Proficy iFIX, Rockwell RSView32, RS Batch, Siemens WinCC, USDATA FactoryLink, VisualBatch, InTouch, etc), Distributed Control System (ABB INFI90, AspenTech IP21, Cim/21, Emerson Delta V, Foxboro I/A, etc), Historians (Honeywell PHD/TDC3000, iHistorian, OSI PI, Rockwell RS SQL, Wonderware IndustrialSQL, etc), Relational Database (DB2, Microsoft Access, Microsoft SQL Server, MySQL, ORACLE, Sybase, Informix, MaxDB, etc), “Standards-based” Protocols (IDBC, OPC, XML, etc.), Manufacturing Execution Systems (Camstar InSite, CIMNET InfoLink, DataSweep Advantage, Honeywell POMS, Mountain Systems Proficy, Wonderware InTrack, etc), CMMS (Cayenta Mainsaver EAM, Datastream, PSDI Maximo, Wonderware Avantis, etc) and Laboratory Systems (Beckman iLIMS, LabSystems SampleManager, PE Nelson SQL, etc).

The “visibility challenge” represents a major obstacle for many organizations. Yet, companies that have deployed SAP’s MII and Neoris’ solutions, have realized tangible benefits such as increases in productivity; continuous business improvement; higher asset utilization and lower total cost of ownership; and a faster return on investment.